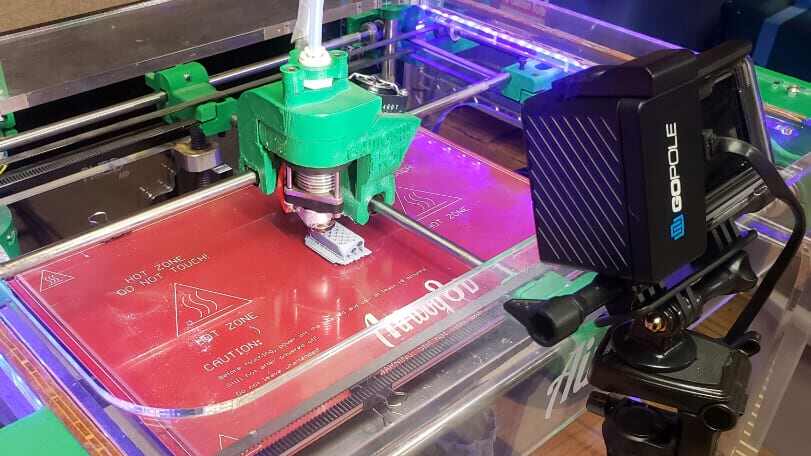

3D printing is a fast and cost effective way to build the prototype parts needed to test design options and make sure the medical cart will work as intended.

HUI Manufacturing designs and manufactures custom medical cart solutions for our customers. The development process we use to get from concept to production is not much different from development processes used by manufacturers across the industry. Inevitably during this development process the need will arise for physical prototypes, and this is where things tend to become expensive. The more rounds of prototypes it takes to get to the final design the more expensive the development becomes. At HUI, we try to utilize prototyping methods that minimize the cost and impact to the time line as much as possible, and one of the ways we do that is through 3D printing.

The absolute best representation of the new product being designed will always be a production grade prototype. However, in manufacturing it’s generally very expensive and takes a long time to setup to build just one of anything. Ultimately before production there will be that first one or two piece prototype build, but because of the cost and time involved in making them you will want to ensure that they will be right. To help mitigate the risks involved in building your first cart it may be necessary to build just components or features of components during the design phase. 3D printing can be a great solution to save time and money making the prototypes needed to ensure the success of your product.

Using a 3D printer, a prototype part can be made in just hours rather than days. This fast design feedback allows us to make iterations of a part in much less time than it would take to build an actual part. Often you don’t even need the entire part, you may just need to make sure one complex feature will work the way it should. In this video we are printing just the lead-in of a shelf support to determine the best geometry that allows for easy removal and installation of a shelf. By doing just the feature we are able to print and test multiple geometries at once and then instantly test and pick the one that gives us the most confidence in the final design.

3D printing is a fast and cost effective way to build the prototype parts needed to test design options and make sure the product will work as intended. 3D printers have come a long way over the years and are basically mainstream. HUI uses the technology to help keep our customers budget and timeline on track.

There are many things to consider when exploring what a custom medical cart will cost to design and manufacture. HUI has a lot of experience designing custom medical carts to a budget. If you’d like more information, or need help with your medical cart solution, contact us today.