In last week’s blog, we discussed core engineering capabilities, and how engineers utilize SolidWorks to analyze and test designs. Today we’ll look into how engineers solve problems and the processes they use to find solutions.

Finding Solutions

Where SolidWorks can provide answers to the hypothetical through simulations, nothing compares the problem-solvig powers of the collaborative brain power of multiple engineering experts bouncing ideas off each other. This well-known tactic is enhanced at HUI by its office formation—no cubicle walls. Engineering teams sit in large rooms without dividers for maximum communication, thus corresponding with LEAN ideals by eliminated time wasted in meetings and emails when engineers can directly ask a question to the room at large and receive answers on the spot.

The Problem Solving Process:

- Identify specific problems

- Divide the issues

- Explore plausible solutions

- Design a new part or product

- Create it

- Test it

- Repeat steps as needed

Let’s say a customer has a product—like a clip.

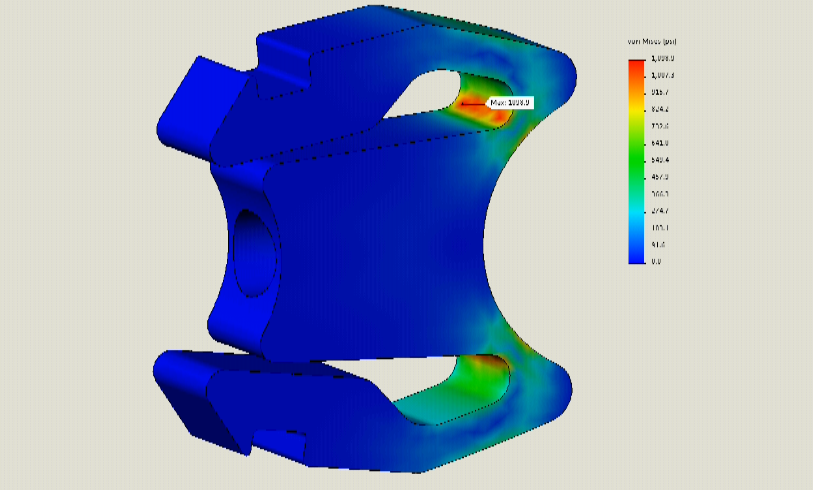

The customer likes the aesthetics and the functionality; however, the clip is prone to breaking. When presented with a problem such as this, the first thing an engineer may do is research the material the clip is currently made of and its material properties. Then, the engineer will search for alternative materials with better properties, apply geometric considerations and perform a Finite Elements Analysis (FEA) study on the original clip to distinguish stress points. Once areas in need of support have been identified, the geometry of the part is changed to reduce or eliminate the stresses reducing the chances for breaking the part.

After all discussions and designs have been decided and finalized, a new clip is built. This first revision will go through a test solution to determine its potential success. Engineers will analyze its progress and make any additional changes as they see fit.

Engineering at HUI

The engineering teams at HUI are well-balanced. We have people who are incredibly creative and those who are very technical—both of which are essential for finding solutions. Most of our engineers have worked on the fabrication floor so they have an in-depth, step-by-step process knowledge of how things are made and assembled, so everyone is more involved in medical cart projects.

Sometimes when it comes to building complex pieces or products, it’s easier just to create it as opposed to spending a lot of time analyzing plausible solutions and outcomes. The ability to have an actual design at hand expedites the engineering and design processes. Because so much of HUI’s work is controlled internally and is supported by fast building flow, it gives our processes a more assertive “fix it if it’s broke” mentality.

Do you have a medical cart design or redesign in mind? Contact us today. Our engineers are up to the task.