The following article was printed in Medical Design and published online. Click here to view the original article online.

A fabrication shop's functions can overlap a bit with those of machine shops, but fabricators usually focus on building structures and devices from steel and aluminum, rather than on machining parts. Hence, fabrication shops perform operations that include welding and assembly, press-brake forming, laser cutting, punching and stamping, and rolling and forming. In the medical area, metal fabrication can handle everything from building a mundane but necessary medical carts that carry life-saving equipment to the cutting and assembly of intricate medical devices such as endoscopic instruments.

Hospitals are a good example of medical facilities that make good use of carts and cabinets fabricated from metal. “It's common for a lot of medical-device manufacturers to suddenly realize at the end of the design cycle that they have forgotten, of all things, a cart for their new device,” says NBD Product Development Manager Mark Collins of HUI Mfg., in Kiel, Wisc., (huimfg.com).

“When off-the-shelf units are unsuitable because they are shaped wrong or too flimsy, many firms turn to custom-fabrication companies like ours. Most customers have similar design requirements: A medical-device cart must be stable, hold a lot of expensive equipment, maneuver easily, and show off a cool, curvy style.”

Because real estate at medical facilities is usually at a premium, most places want the smallest footprint and the lightest weight cart possible, says Collins. “Of course, there are always trade-offs. For example, a narrow wheel base necessitates a rigid cast base. That's not necessarily bad because carts get abused during constant use and when they are not durable enough, they can collapse. A cast base would seem to fit the bill here, but it does have drawbacks. These include tooling and development times, inconsistent surface finishes, larger annual build volumes to offset tooling investment, and the possibility of catastrophic failure due to crack propagation in a brittle material,” he says.

Because real estate at medical facilities is usually at a premium, most places want the smallest footprint and the lightest weight cart possible, says Collins. “Of course, there are always trade-offs. For example, a narrow wheel base necessitates a rigid cast base. That's not necessarily bad because carts get abused during constant use and when they are not durable enough, they can collapse. A cast base would seem to fit the bill here, but it does have drawbacks. These include tooling and development times, inconsistent surface finishes, larger annual build volumes to offset tooling investment, and the possibility of catastrophic failure due to crack propagation in a brittle material,” he says.

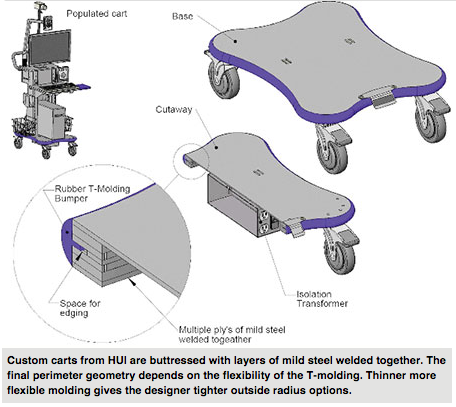

To get around this problem, Collins' company devised a metal-fabrication method that provides all the positive aspects of a cast base without its drawbacks. The method entails stacking layers of mild steel around the perimeter of the base and welding them together. The thickness of the material depends on the weight requirements of the base and the selection of the rubber molding around the outside perimeter. A small space or slot in the side wall extending around the perimeter provides room to insert a plastic T-molded strip. “This provides a tough bumper and also makes the base appear much thicker than it actually is. What's more, the resulting inside cavity makes for a great place to mount equipment, such as an isolation transformer,” he says.

To get around this problem, Collins' company devised a metal-fabrication method that provides all the positive aspects of a cast base without its drawbacks. The method entails stacking layers of mild steel around the perimeter of the base and welding them together. The thickness of the material depends on the weight requirements of the base and the selection of the rubber molding around the outside perimeter. A small space or slot in the side wall extending around the perimeter provides room to insert a plastic T-molded strip. “This provides a tough bumper and also makes the base appear much thicker than it actually is. What's more, the resulting inside cavity makes for a great place to mount equipment, such as an isolation transformer,” he says.

The design also is flexible enough to fine-tune the amount and location of extra ballast. “For example, take a medical device that has a fluid reservoir toward the front of the cart,” says Collins. "Merely adding weight to the back and removing it from the front by changing the thickness of the steel layers solves potential balance problems. The inside cavity also allows flexibility for mounting casters. Plate-mount casters can easily be attached anywhere and stem-mounted casters can be accommodated by cutting clearance holes in the layers of steel.”

The design also is flexible enough to fine-tune the amount and location of extra ballast. “For example, take a medical device that has a fluid reservoir toward the front of the cart,” says Collins. "Merely adding weight to the back and removing it from the front by changing the thickness of the steel layers solves potential balance problems. The inside cavity also allows flexibility for mounting casters. Plate-mount casters can easily be attached anywhere and stem-mounted casters can be accommodated by cutting clearance holes in the layers of steel.”